Photos Courtesy of Cat Foam Concrete Lifting & Leveling in Houston

Slab Jacking is the process of raising and leveling unstable concrete slabs that have sunken due to age, improper installation, poor soil conditions, or soil erosion. The material used for this type of repair includes polyurethane foam which fills in voids under the slab then expands and hardens into a solid surface with incredible strength and durability.

As the foam expands, it raises the concrete to the desired height for a smooth transition. This method prevents further sinking while also preventing water damage from occurring underneath it without a negative environmental impact.

The ultimate benefit to Slab Jacking is the substantial cost savings and quick process over concrete replacement.

Why Concrete Leveling Is the Best Alternative to Replacement

The purpose behind lifting concrete slabs include:

- Poor foundation design,

- Settling soils beneath your home or commercial property.

- Uneven settlement among different areas on your property, therefore, causes some parts to sink lower than others.

The process of a polyurethane injection repair project is to drill 5/8-inch diameter holes through a cement slab. Contractors inject high-density polyurethane foam through the holes, beginning an expansion process filling all the voids below the concrete. As the foam hardens and expands, it raises the concrete slab.

Concrete Leveling With Mud Jacking

Concrete leveling, also called Mud Jacking, is a long-term, cost-effective alternative to the time and expense of concrete removal and replacement.

What Is Traditional Mudjacking?

Typical mud jacking is a blend of soil and cement fill material with an injection process below the surface providing concrete leveling. The process fills voids to stabile the soil.

Polyurethane Concrete Raising with Slab Jacking versus Mud Jacking

One of the significant advantages of concrete lifting and leveling with foam material is its lightweight versus the standard Mud Jacking process. In fact, polyurethane material is 2% of the weight of mud slurries.

Foam systems typically have a longer life cycle. It is a waterproof material resistant to sub-surface water and vibration that will break down mud slurries.

Professionals report that the concrete leveling life span of traditional Mud Jacking is 7 to 12 years while polyurethane foam will endure indefinitely.

Polyurethane Concrete Raising: The 5 Step Process

As mentioned, an uneven, sagging concrete surface is a result of voids below the slab. Sub-surface groundwater, sloping terrain, lack of adjacent support, tree roots, sinkholes, and/or vibration all create voids. Water from roofing with inadequate gutters or downspouts contributes to creating voids.

As mentioned, an uneven, sagging concrete surface is a result of voids below the slab. Sub-surface groundwater, sloping terrain, lack of adjacent support, tree roots, sinkholes, and/or vibration all create voids. Water from roofing with inadequate gutters or downspouts contributes to creating voids.

The 5 Step Process Includes;

- Analysis of the cause with a solution.

- To raise concrete, drill 5/8 inch holes through the slab.

- Inject polyurethane foam through the drilled port.

- Concrete Lifting – Slabs will raise to ideal height to match adjacent surfaces.

- Patch Holes, then Fill Cracks and Expansion Joints.

What Are The Top 10 Benefits Of Polyurethane Concrete Lifting?

- Easy Access via Hoses to Hard to Reach Areas with Low-Pressure Lifting process.

- Quick Process as little as 45 minutes in some cases. It fills voids while stabilizing already weak soil.

- Avoids expensive concrete replacement.

- Avoids damage to landscaped areas.

- Cost-Effective – 20% to 50% of the cost or replacement.

- Accurate concrete raising of slabs to level matching adjacent areas.

- Control Water Flow in Trenches.

- Moisture Proof – As the foam expands it pushes the water out of voids.

- Multi-Use – Lifts and raises slabs, stairs, and foundations.

- Marine Use – Polyurethane concrete raising for Sea Walls, docks, and bulkheads.

Slab Jacking Equipment For Polyurethane Concrete Raising

Polyurethane Concrete Raising foam is a liquid injected through a drilled port in a slab. The liquid will expand beneath the slab. It’s like shaving cream that expands into foam. The polyurethane foam raising hardens as it expands. As it cures and expands, it has incredible power and strength

Concrete Raising Equipment:

- Trailer or Truck To Haul Equipment

- Drilling Holes – Drill and bits for small and large holes

- Foam Injection Gun,

- Injection Port

- Hose 150 Feet +

- Concrete Raising Foam

- Crack Filler

How Much Weight Can Concrete Raising Foam Lift?

Raising concrete with a polyurethane injection system works for both small and large projects. It’s strong enough to raise a sinking foundation in a home. Measurement of weight lifted is in pounds per square foot. With 2,000 lbs. in a ton, the void-filling foam can lift a few tons per square foot. That’s more than enough for driveway repair, pool decks, sidewalks, and patios.

How Much Does Slab Jacking Cost?

Slab Jacking’s average cost is 20% – 50% of the price to replace concrete. Below you will find approximate pricing for residential home and commercial use.

Typically, the average price ranges from $4.50 – $15.00 per square foot depending on the location and scope of the project.

Raising concrete is a quick, low construction, low mess process with uneven slabs raised in just 1 to 2 hours in some cases. Factors that impact time and expense are the size of the voids below the surface. Each concrete slab requires a different amount of polyurethane to raise and settle a slab.

Cost Of Replacement with New Concrete

Replacement is a big job requiring heavy equipment to break cement and remove. New installation is a process. It begins with excavation followed by grading and form construction. Local Concrete companies coordinate concrete delivery needs so concrete pouring, smoothing, and leveling happen on schedule. Then, contractors remove and discard forms. Frequently, you will need to repair adjacent landscaping.

Cost of Concrete Lifting Foam For Sidewalks and Walkways

Cost of Concrete Lifting Foam For Sidewalks and Walkways

A 200 square foot walkway that is approximately 6 feet wide and 33 feet long will cost $900 – $3,000. Keep in mind, the repair will take a few hours. Replacing new concrete is a messy construction project. Replacing a sidewalk with new concrete requires removal, forms, and installation. Grass and Landscaping will get damaged adding additional fees. Overall replacement cost can increase the expense by 50% – 100% or more plus the time factor.

Cost of Concrete Lifting For Porch and Patios

A 15’x 15′ patio is 225 square feet. Foam Jacking and Leveling Cost will be in the ballpark of $1,000 – $3,000 based on a per square foot cost of approximately $4.50 – $12.00 per square foot. Your Contractor in most cases will be in and out in a few hours (or less) without damaging the surrounding landscape, even if your patio is in the rear of your property. The foam injection system has a long hose to reach hard-to-get areas. This means projects are easily accessible without the concern for damage to your property. Analyze each project prior to obtaining an accurate estimate.

Cost of Concrete Leveling and Lifting For Uneven Concrete Driveways

Uneven slabs occur because of many factors. Expansive soils are one cause but not the only reason unevenness occurs. Different grades for different directions are another example of poor grading during construction. Water runoff will create voids resulting in a sunken concrete slab. Foam leveling fixes uneven concrete slabs, cracks and expansion joints.

Concrete Foam Leveling For Pool Decks

Let’s use an 800 SF Pool Deck as an example.

It’s common that only one area of the pool deck requires concrete leveling. In many cases, you may have some areas with sunken concrete that are more or less than others.

Extremely sunken areas will require more foam hence increased expense. In order to match the level of adjacents slabs, the contractor will lift each area of the pool deck. As a result, the repair cost will be surprisingly low since you may only need partial lifting.

Cost can range from $1,000 to $3,000 or more depending on size.

Basement Floors – Concrete Leveling and Repair

A common question is “Can My Basement Floor Be Leveled”? If your basement floor is sinking, the best option may be slab jacking. Removing and replacing your cement basement floor is a challenging, time-consuming, and expensive construction project.

The cost for concrete leveling in a basement based on square foot pricing for a 500 SF Floor will range from $2500 – $7500 based on $5.00 – $15.00 per square foot. Keep in mind, this is a ballpark estimate.

Experts need to evaluate the cause of a sinking slab. Soil erosion beneath the basement floor may result from faulty gutters with excess water traveling along your foundation and underneath the slab.

Garage Floor Leveling

Garage Floor Leveling

Problems with sinking garage floors happen when water issues erode the soil beneath and create voids in need of filling. A typical 2 car garage is 400 to 500 square feet. Based on per square footage mentioned above, pricing the garage floor repair would be approximately in the range of $2,000 to $7,000 pending evaluation of the scope of the repair.

Once leveled, you can resurface your garage floor with decorative epoxy like the picture shown here.

How To Fix Sinking Central Air Conditioning Systems and Generators

Your central air conditioning system and generator for powering your home or business typically are typically next to your foundation. Note the photo here.

Water runoff over time will create voids below the slab that supports your systems. When this happens, the weight of the HVAC and Generator will pull hoses and electric lines away from your home or commercial property.

The potential for damage to your electric lines, hoses, and brackets is very real. These potentially dangerous situations can develop if not taken care of properly and quickly. Polyurethane foam is an easy and quick concrete repair remedy to an uneven Portland cement or stone supporting slab.

A simple foam injection provides structural support by filling voids, stabilizing soil, and levels your Air Conditioner and Generator saving you thousands of dollars.

Raising and Leveling Concrete Stairs

Foam jacking is the perfect solution for stabilizing concrete stairs that are sinking due to soil erosion. This highly effective method prevents structural damage and saves you thousands in repairs down the line!

It’s strong enough to add structural support for commercial use and extremely durable for long-term performance.

If your soil is eroding, foam injections accurately lift and level underneath stairs. This inexpensive solution will prevent you from having cracked concrete or the need for newly installed masonry replaced as well!

How to Fix A Sinking Foundation With Slab Jacking

Slab jacking is a repair method used to level and raise your foundation. The process injects polyurethane foam underneath it for stabilization, which can be strong enough for commercial use!

Slab Jacking also has excellent durability that will last long-term whether you are using it at home or in an office building; saving you thousands of dollars over more expensive options.

Where to Use Polyurethane Lifting for Industrial and Commercial Slab Foam Leveling?

Slab jacking Industrial Warehouse Facilities

The issue of unstable and uneven flooring is a common problem in warehouses. Cement slabs often get displaced by traffic flow, poor compaction under the soil, or heavy equipment which can cause unsafe working conditions as well as maintenance issues with machinery- all leading to lost productivity for businesses!

Culvert Repair With Foam Injection

Culverts are structures built under level ground allowing water to flow freely. This may be under a roadway, walkway, or bridge. They can be in the form of a concrete culvert or metal or pipe.

Constant water flow and run-off from rain create voids and inevitable sinking. Foam injection solves the problem quickly and inexpensively by pushing out water while filling voids with a long term, water impervious solution.

Raising Uneven Concrete for Greenhouse and Nurseries

Nurseries and greenhouses move plants with carts and hand trucks. It can be extremely annoying when tires get stuck or cannot easily get over an uneven surface. Foam Jacking will make for a level, smooth transition over the concrete slab.

Slab Jacking For Sea Walls

Tidal changes in harbors and waterfront areas, sloping areas near streams and ponds, cause soil erosion causing sea walls to sag and sink. Polyurethane Foam injections into the voids pushes water out. The process will lift and level sea walls avoiding expensive replacement.

Slab Jacking Concrete Leveling at Airports

Foam injections also lift and level uneven concrete runways. Sidewalks, baggage areas, shipping docks, and ramps are all suspectable to sinking. Foam Jacking Is a cost-effective solution to quickly repair rather than replace. Lifting and stabilizing slabs to a precise, accurate height allows for a smooth, durable transition.

Leveling For Sinking Railroad Tracks & Crossings

Railroad tracks experience exposure to many different types of weather, all with the potential for causing damage. One way that this happens is through weak soils and subsoils which can lead to voids or depressions in rail bedding as well as sinkholes (subsidence).

The punch bowl effect occurs when water seeps into an area beneath soil because there’s not enough pressure from above pushing outwards against gravity. Holes form at these locations making them susceptible to (UWI) underground water invasions.

Foam injection will fill voids will a long-term water-resistant solution.

Concrete Leveling and Lifting with Slab Jacking For Agricultural Buildings

Foam jacking is the most cost-effective way for raising settled concrete in agricultural buildings. Replacing a concrete floor can be time-consuming and expensive, but it doesn’t have to be this way. There are other options for leveling out your floors besides jackhammers and bulldozers.

Foam injection technology can lift up the foundation of a building by injecting into small holes drilled into the existing structure. This concrete repair method is much faster than traditional methods like jackhammers or bulldozers, making it more cost and time-effective!

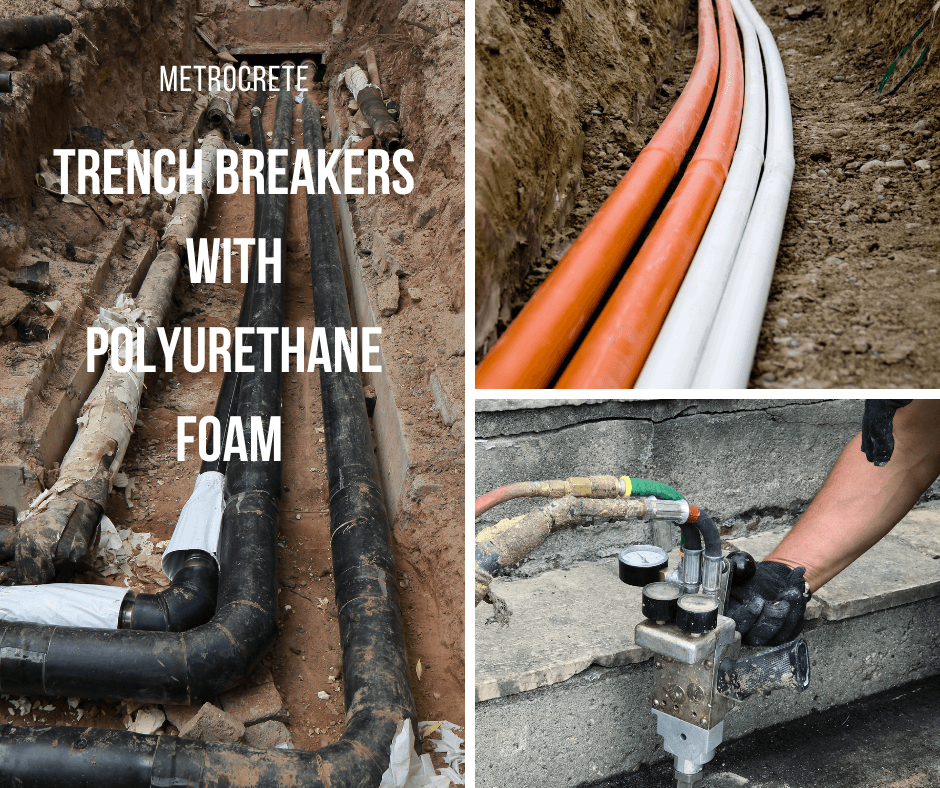

Trench Breaker Spray Foam Insulation

Before digging a trench for pipelines or utilities, there are a few important considerations.

- Metal pipes are susceptible to corrosion from subsurface water and damage from moving rocks.

- Below-grade water can move through a trench unless there is a breaker to stop the flow.

- Spray pipes to prevent corrosion. It serves a dual purpose as a guard against rock damage.

- In sloping areas, the injection foam stops water flow becoming a trench breaker as an alternative to using heavy sandbags.

Filling Sink Holes

Sinkholes are voids in the ground caused by numerous factors. It could be from construction projects where workers buried wood debris in the ground. When wood rots, it creates a sizable void.

Subsurface groundwater traveling through rocks can carve voids underground. Leaking drains caused by freeze/thaw issues, wells and underground pipes can cause voids. The spray system expands into rigid foam filling the voids in sinkholes.

Concrete Leveling & Repair for Electrical Sub Stations

There are thousands of electric sub-stations supporting power lines nationwide. Click Here For Information https://en.wikipedia.org/wiki/Electrical_substation

A typical concrete slab is 2,000 – 3,000 SF. When the slabs sink, they can impact the structure. Polyurethane Jacking is a quick, inexpensive, long-term solution for raising concrete preventing expensive damage and repair

Find a Slab Jacking Contractor In Your Area

If you are looking for a free estimate, contact a professional Slab Jacking Company near you, click the Contractor Link here or on top of the page.