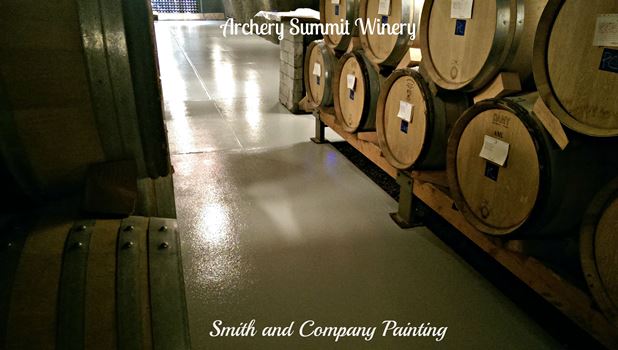

Smith and Company Painting recently completed the installation of epoxy floor coatings at the Archery Summit Winery in Dayton Oregon 45 minutes from Portland.

Epoxy Flooring in Archery Summit Winery Volcanic Rock Caves

Archery Summit Winery is uniquely located in Dundee Hills, Ribbon Ridge and the Willamette Valley with remarkable conditions for production of Pinot Noir.

Smith and Company installed epoxy flooring in the natural caves beneath the winery, which were modeled after the underground caverns of Burgundy’s Cote d’Or. Formed from natural volcanic rock, the caves maintain a temperature of 55- 59 degrees with humidity below 75 degrees. To showcase the unique production of their wines, Archery Summit keeps the caves open to visitors year round.

As a result, the flooring choice for proper performance in this environment is critical for cleanliness, light reflection and long-term wear.

Epoxy Flooring at Archery Summit – Project Details

Location – 18599 NE Archery Summit Road, Dayton Oregon, 97114

Client – Archery Summit Winery

Contractor – (503) 894-6099 For contact Information, visit Smith and Company Painting

Project Size – 1,000 SF approximately

Problem – Old epoxy flooring was difficult to maintain and clean due to excessive wear for over 10 years. Scratches in old coating prevented light reflection.

Solution – The old epoxy had a strong bond to the concrete floor. As a result, rather than removing coating, the surface was sanded and recoated. To prevent staining from the red wines, a urethane sealer was applied.

Time to Complete – 4 Days

Cost of Project – Approximately $5.00 Per Square Foot

Products Used in Project – Epoxy and Urethane Coatings

General Polymers – GP3745 Self Leveling Epoxy – Color was a light silver/gray. This epoxy choice provides an ideal coating for application over the old sanded epoxy.

It allows for flexibility subject to conditions. Fast cure hardeners may be applied. Typical cure time in an area like the winery caves with a normal hardener would be 16-24 hours. As a comparison, cure time in 72 degree environment is 6-12 hours, and in 92 degrees, cure time is typically 4-8 hours.

In this case, a fast hardener accelerated the cure time. As a two-component epoxy, a fast cure hardener will reduce the risk of cross link separation. GP 3745 is also available with an antimicrobial agent. Get Details About GP 3745

General Polymers 4638 Polyurethane – This top protective coating is ultra durable with high gloss and light reflectivity. It is chemical and abrasion resistant making it ideal for use in wineries, retail stores, airplane hangars, industrial facilities and other high wear environments. It is a fast cure sealer. Applied at a rate of 3 wet mils per coating. GP 4638 Data Sheet

About Smith and Company Painting McMinnville, Oregon

Smith and Company is a family owned painting and coating business serving commercial and residential customers from Salem to Portland Oregon for over 50 years. During the past 5 years, Smith and Company has expanded their commercial concrete epoxy flooring business.They are currently adding marine coating to their offered services due to their close proximity to Portland Harbor.